Metal Milling

Precision milling

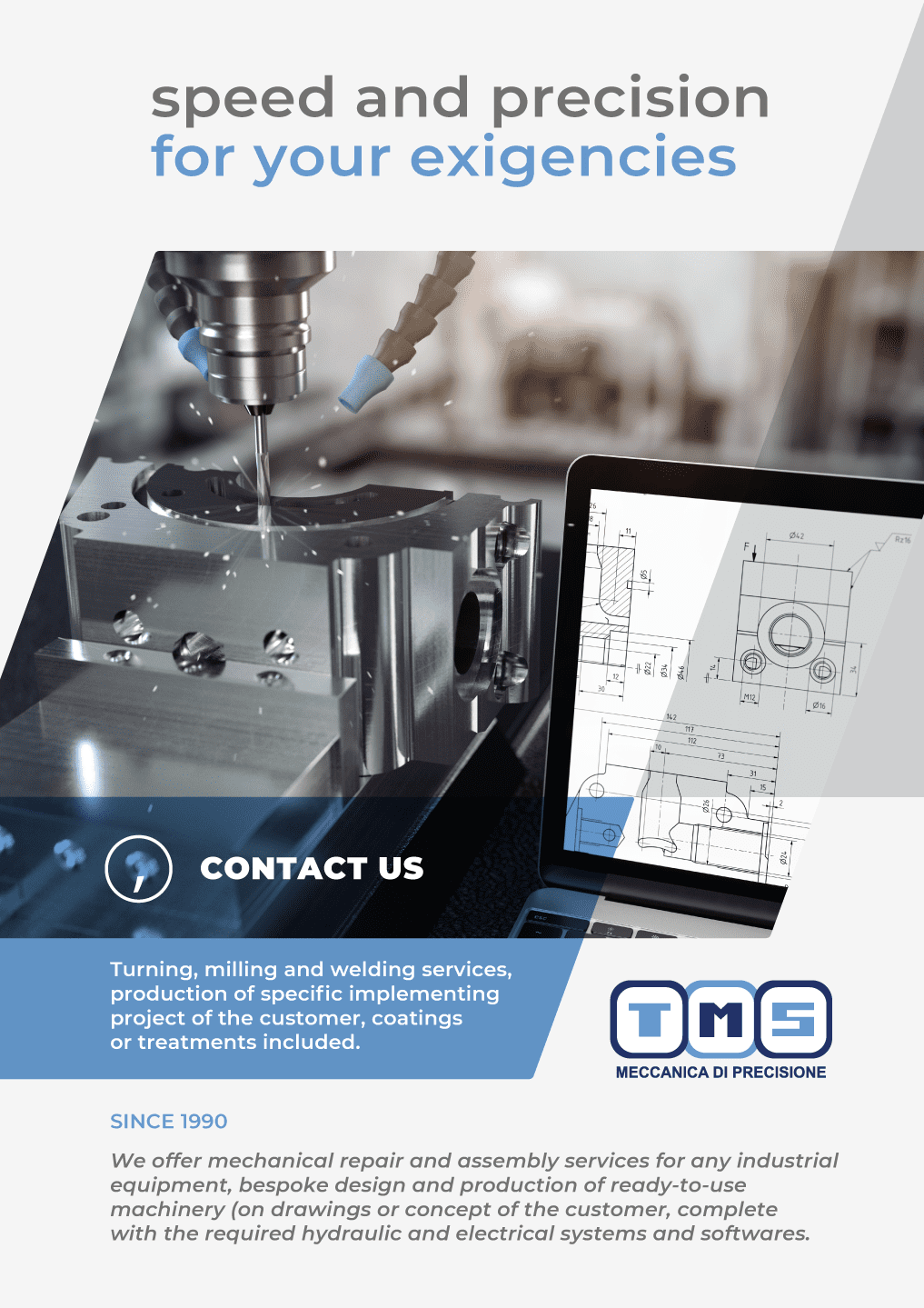

With our precision milling service we guarantee excellent results in terms of punctuality, speed and quality in the production of mechanical components both in metallic and plastic materials, implementing project of the commissioner or producing on sample.

We are specialized in third-party milling services and produce milled components in metals (stainless steel, alloy steel, aluminum and its alloys, copper, brass and bronze) as well as in plastic materials (Teflon, nylon, polyvinylchloride PVC, Polyamide PA, polythiophene PT, polyurethane PUR), crafted with technological CNC machines.

Thanks to the constant upgrade of our machinery, which enables us to deal with several different high-precision processes, and a flexible business-organization, we are able to treat and produce every requested component, guaranteeing at the same time low-cost production, high-quality products, fast execution and delivery on time.

With its precision mechanical milling service T.M.S. turns to small and medium-sized enterprises acting in the industrial automotive branch (textile, chemical, papermaking, furnishings, food-packaging, etc.) as well as companies offering maintenance services, which need to collect specific bespoke components in short time.

Thanks to the constant upgrade of our machinery, which enables us to deal with several different high-precision processes, and a flexible business-organization, we are able to treat and produce every requested component, guaranteeing at the same time low-cost production, high-quality products, fast execution and delivery on time.

With its precision mechanical milling service T.M.S. turns to small and medium-sized enterprises acting in the industrial automotive branch (textile, chemical, papermaking, furnishings, food-packaging, etc.) as well as companies offering maintenance services, which need to collect specific bespoke components in short time.

Milling of components and small parts in metallic or plastic materials

The milling process with CNC machines enables us to produce bespoke components and small parts, even for small and middle-sized lots, developing the project with the use of CAD/CAM software and producing a first prototype, which has to be approved before starting the final production.

Starting from the solid block, part of the material is cut and removed by a sharp rotating tool (milling cutter); the process is dived in two main stages: in the first one (roughing), exceeding material is roughly removed; in the second one (finishing), the tool is programmed to work in detail, in order to obtain a product in compliance with the shape-dimension-surface required.

The T.M.S. milling department ensures the development of both easy and complex projects, with reduced dimensional and geometrical tolerances, and it’s equipped in the following way:

Starting from the solid block, part of the material is cut and removed by a sharp rotating tool (milling cutter); the process is dived in two main stages: in the first one (roughing), exceeding material is roughly removed; in the second one (finishing), the tool is programmed to work in detail, in order to obtain a product in compliance with the shape-dimension-surface required.

The T.M.S. milling department ensures the development of both easy and complex projects, with reduced dimensional and geometrical tolerances, and it’s equipped in the following way:

- “Jezz10” FANUC 0i MF CNS vertical machining center (2019) – useful dimensions: 1000 x 400 x 500

- “MV” FANUC 0i MF CNS vertical machining center – useful dimensions: 1800 x 550 x 450

- “Siemens 850D” FAMUP vertical machining center (2006) – useful dimensions: 1200 x 550 x 600

- “Selca 3045D” FAMUP vertical machining center (2000) – useful dimensions: 1200 x 550 x 500

- “Kondia Visualizzate” manual milling machine

- "Wele CV-1060" CNC milling machine - useful dimensions: 1000 x 400 x 500

Thanks to its high-skilled staff and the great efficiency of its milling machines, T.M.S. has reached remarkable results in terms of fast production and respect of the delivery terms agreed with customers.

Moreover, counting on a quality control department, equipped with micrometric air-conditioned room, baseboard and “Alpa” altimeter, the company can guarantee maximum precision in the production.

Moreover, counting on a quality control department, equipped with micrometric air-conditioned room, baseboard and “Alpa” altimeter, the company can guarantee maximum precision in the production.

Why should you turn to T.M.S. for mechanical milling services of metals and plastic materials

Born in the 90s dealing with construction and maintenance of carts and printing tables, today T.M.S. is specialized in the branches of precision mechanics and industrial automation, offering turning, milling and welding services and producing metallic or plastic components on design or sample of the customer, treatments or coatings included.

Moreover, the company offers an exclusive department dedicated to repair and assembly a wide range of machines and “turnkey” services for the design and the development of textile and industrial machinery implementing project or concept of the commissioner, complete with hydraulic and electrical systems and software.

Giving prompt and proper answers and working in full cooperation with customers, the company provides milling services, standing out for fast delivery of industrial components designed on specific demands of the commissioners and developed with the highest quality standards. High-quality production is guaranteed by the perfect organization of our resources and workflow, by the high professionality of our technicians, by the selection of raw materials and by the strong bias in problem solving, which enable T.M.S. to ensure fast and flexible services for different purposes.

Moreover, the company offers an exclusive department dedicated to repair and assembly a wide range of machines and “turnkey” services for the design and the development of textile and industrial machinery implementing project or concept of the commissioner, complete with hydraulic and electrical systems and software.

Giving prompt and proper answers and working in full cooperation with customers, the company provides milling services, standing out for fast delivery of industrial components designed on specific demands of the commissioners and developed with the highest quality standards. High-quality production is guaranteed by the perfect organization of our resources and workflow, by the high professionality of our technicians, by the selection of raw materials and by the strong bias in problem solving, which enable T.M.S. to ensure fast and flexible services for different purposes.

How to request us a free quotation for mechanical milling services

Requesting quotations or advices for metal and plastic milling services is easy and without commitment. T.M.S. team can be contacted from Monday to Friday 8.00-17.00 at +39 031560052 or by Email at tms@tms-srl.it

T.M.S srl is located in Guanzate – Como, XXIV Maggio 12 street and operates both in Italy and abroad.

T.M.S srl is located in Guanzate – Como, XXIV Maggio 12 street and operates both in Italy and abroad.

FURTHER QUESTIONS?

Contact us

Our company is located in

Via XXIV Maggio 12

22070 Guanzate (Co)

Telephone number: +39 031 560 052

E-mail: tms@tms-srl.it

Via XXIV Maggio 12

22070 Guanzate (Co)

Telephone number: +39 031 560 052

E-mail: tms@tms-srl.it

Business hours

MONDAY - FRIDAY

08:00 - 17:00

SATURDAY – SUNDAY

CLOSED

T.M.S. srl

We are specialized in third-party precision mechanical and metal processing (turning and milling), working with specific production units, precision machinery with turning machines and CNC machining centers.